Product Information

Categories: BY RAW PRODUCTS, Delicacy, snacks, nutritional supplements, PODĽA PRODUKTOV, Vegetable products, VegetablesVacuum deep frying of vegetables is an innovative way of processing vegetables into tasty and healthy chips that are not only delicious but retain all the beneficial ingredients and vitamins that the vegetable contains. Vegetable chips provide enough energy between meals. Vegetable chips are a great alternative to raw vegetables, they are tasty, crunchy and can always be handy.

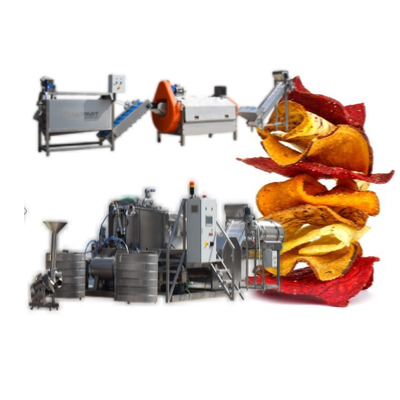

The line is designed for complete processing of raw vegetables into chips. The result is a healthy flavored snack.

Making healthy vegetable chips has never been easier. With the NORMIT production lines you can start production right away.

Stand out from your competition and produce healthy snacks!

CONTACT USFilter produktov

- BY INDUSTRY (51)

- BY PRODUCT (0)

- PODĽA PRODUKTOV (63)

- All (29)

- BY RAW PRODUCTS (58)

- BY ABC (49)

Description

Vegetable chips are a source of vitamins A and C. One portion of chips contains up to 25% of the recommended daily dose of vitamin A and up to 20% of the recommended dose of vitamin C. In addition to vitamins A and C, they also contain minerals such as calcium and iron.

Frying – using vacuum (at lower temperature) represents a unique, modern method of heat processing, allowing to achieve the unique characteristics of the final product. Healthy vegetable chips production lines include a vacuum frying equipment that allows frying of the material to a crispy state at less than 120 °C without acrylamide formation *. The fried material doesnt contain carcinogenic elements and is a healthy alternative for most snacks on the market. Considering the established connection among consuming of foodstuff and human well-being, customers are choosing food with caution and regurlarly favour healthier food. One of the concerns consumers have is the high oil or fat content. Products with bigger fat content are linked with many issues effecting personal health and can cause illnesses like:

Obesity

Cancer

Type 2 Diabetes

Probability of cardiovascular ilness

For the production of modern industrial frying equipment, the technology designed especially for decreasing risks to our health are used. For instance. an enhanced oil filters are made for extending its duration. Nevertheless, it is not adequate for eliminating all the issues connected with deep frying.

Why would frying under vacuum be healthier?

Frying under vacuum – an other method for preparing material at lower pressure as well as lower temperature. It has been confirmed that the vacuum makes the manufacturing process faster, creating delicious and healthy products at the same time. Processing by using this machinery can be characterized as drying as well as cooking using hot oil.

When using vacuum, water is eliminated from the material very shortly. This makes the processing faster, and as a result, the vacuum frying is more effective than atmospheric one in terms of productivity. If the oil doesnt enter the open pores of the material, the final product will have a lower oil content (up to 7%) compared to 40% gained with standard frying!

Thanks to the lower pressure used for processing in a vacuum frying machine, frying of products can happen at lower temperatures – 85 ° C to 120 ° C. The oil does not content any carcinogenic elements, it remains fresh for a long period compared to atmospheric deep frying machines.

During frying using lower temperatures, the material holds its organic color, flavor, aroma and sources of nourishment. Frying under vacuum makes fruit or vegetable into healthy eats, which can be extremely favored and turn into a valuable substitute to standard chips.

Frying under vacuum allows you to produce light snacks or eats of higher worth with low electricity consumption when you compare it to standard deep fryer, offering the equipment holder a competitive benefits.

Commercial benefits:

Quick frying: bigger output while low power expenses

Oil preserving – oil remains fresh longer, no burning, doesnt retain arome from the last fried material, rarely needs to be changed

Less odor and aroma intensifiers are required

A competing product in the food market

Chips produced in a vacuum frying equipment are better than competitor’s because:

Less oil – up to 7%

Attractive color – almost the same as original, chips do not turn dark, without any black dots on the exterior

No burning of oil – without bad odor or aroma

The product keeps essential characteristics

Almost no acrylamide – 94% lower as in conventional deep fryers

No carcinogenic elements

*COMMISSION REGULATION (EU) 2017/2158 of 20 November 2017 laying down measures to minimize acrylamide levels in food

SDFa

Related Products

Frozen butter homogenizer

Frozen butter homogenizer is intended for the mechanical processing of frozen blocks of butter, cheese, spreads, margarines or other products without first being subjected to higher temperatures and thawing, thereby preserving its properties, reducing processing time and preparing the product for immediate use in another manufacturing process or for packaging (change from -18 ° C to +6 ° C).

Butter homogenizer

The frozen butter homogenizer is designed for the mechanical processing of blocks of butter, cheese, spreads, margarines or other products at a temperature of +8 to + 13 ° C without being previously exposed to a higher temperature, thereby preserving its properties, reducing processing time and prepare the product for immediate use in the next manufacturing process or for packaging.

Rotary vacuum diffuser

Vacuum diffusion is the process by which the air inside the product is removed by vacuum and the released pores are filled the flavor, vitamin or other substances.

Vacuum homogenizer VMG M LAB

Vacuum homogenizer - mixer VMG M is an ideal solution for the production of pilot batches of products and industrial production of a wide range of products of small and medium production.

Technical data and available models on request from our sales department

CONTACT USVacuum evaporator SQE

Vacuum evaporators of the SQE series are designed for evaporation of water, thickening and cooking of a wide range of viscous products under vacuum, cooking at lower temperatures, thus preserving the natural taste, aroma and color of the product.

Honey homogenizer

Pasting or creaming honey is a controlled crystallization of honey. Pasted honey is also called creamed honey, because of its consistency resembles cream. Pasted honey retains all valuable substances, is easy to spread, easy to collect, does not leak, drips and does not change its properties when stored. The creamy consistency is achieved by preventing the formation of large interconnected honey crystals, the crystals being fine and unconnected.

Company NORMIT FOOD s.r.o. designs and manufactures a customized line according to your requirements and needs.

CONTACT USProduction line for making dried fruit

We will design a tailor-made solution, exactly according to your requirements, from the loading of fruit, washing, peeling, slicing, drying to the packaging of the finished product.

Company NORMIT FOOD s.r.o. designs a solution and manufactures a customized line according to your requirements and needs.

CONTACT USForming machine – former for hamburgers

Line for production of semi-finished meat products

The line is an ideal solution for the production of meat products such as meatballs, burgers, meat pancakes and the like.

Company NORMIT FOOD s.r.o. thanks to its many years of experience and teams of experts, will design a solution and produce a tailor-made line according to your requirements and needs.

CONTACT USVacuum evaporator – concentrator SweetStuff

Vacuum evaporator - concentrator is designed for cooking a wide range of products - confectionery mixtures, jams, caramels, sauces, including high-viscosity and low-liquid products, as well as concentrating various extracts and similar products in the food, pharmaceutical, chemical and other industries.