Description

Thanks to its favorable price and versatility in the production of various types of products, it is the optimal solution for start-ups and for production of pilot batches, formulation of recipes and testing of new types of production.

Processes:

- Heating, cooling

- Mixing

- Vacuum

- Dispersion

- Emulsification

- Homogenization

- Dearation

Examples of use for different sectors of the industry

- – Milk – soft curd, kefir, condensed milk, reconstituted milk powder, cream.

- – Fats – mixture of oils, margarine, mayonnaise, paste

- – Fruit and vegetables – jam, ketchup, sauces, puree, pastes

- – Confectionery – creams, fillings, chocolate-nut pastes, chocolate glaze, honey.

- – Non-alcoholic beverages – juices, nectars, drinks

- – Cosmetics – creams, shampoos, balzams, gels, ointments, toothpaste

- – Farmaceutics – ointments, emulsions, gels

- – Chemicals – cleaning agents, adhesives, varnishes, polish, disinfectants

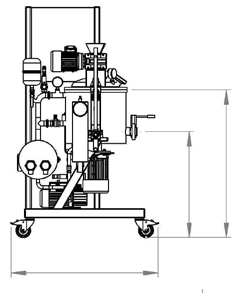

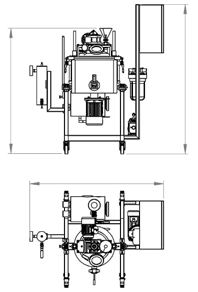

The equipment consists of a working vessel with an insulating layer, a heating / cooling jacket, a low speed stirrer with scrapers, a bottom rotor-stator homogenizer. The container is mounted on rotating supports with position fixation.

The product is unloaded from the homogenization vessel simply and quickly thanks to the tilting system (with manual or mechanical drive depending on the vessel volume). The lid is easy to open and is hermetically fixed with four screws in the closed position.

Depending on the customer’s requirements and needs, there is a choice of different levels of automation: weighing and dosing of raw materials, heating and cooling temperature control, emulsification process, homogenization, regulation of agitator speed and vacuum level.

Vacuum – the process of air removal allows to reduce the processing temperature of the product, maximizing its utility properties.

Mixing – the geometry of the working homogenizing vessel and the special shaped stirrer ensure uniform mixing of the product without dead zones. Thanks to special “floating” scrapers, the product does not stick to the walls of the container and does not burn, they also help to maximize the heat exchange between the wall and the product.

Homogenisation – the integrated rotor-stator homogenizer located in the bottom of the container ensures fast and efficient dispersion, emulsification and homogenization. The obtained finished product looks attractive, has a stable and homogeneous structure, does not separate and has a long shelf life. Recirculation and discharge of the product is also provided by means of a homogenizer, it is not necessary to use auxiliary pumps, which increases hygiene and ease of maintenance of the equipment.

Heating and cooling – the jacket for heating and cooling makes it possible to carry out heating, melting and cooling processes in one device. Optionally, “direct steam injection into the product” allows to significantly reduce the heating time and shorten the processing time of the product.

The automated control system eliminates the human factor and guarantees consistently high quality of finished production from batch to batch.

Benefits

- Low purchase costs for the equipment, ideal for start-ups, for developing new recipes and for manufacturing pilot batches.

- Possibility of processing a wide range of liquid, pasty, viscous and highly viscous products

- Minimum filling of 15% of the vessel volume

- High performance

- Reliable design and long trouble-free operation

- Rapid transition to the production of a new kind of products

- Easy operation, maintenance and sanitation

- Low operating costs

Optional

-

Funnel for inserting ingediences during the working cycle

-

Tilting of the container

-

Different types of stirrers

-

Adjustable stirrer speed

-

Direct steam injection into the product

-

Different levels of automation

-

GMP design

VMG M LAB is the basic model and is suitable for the production of pilot batches of products and for industrial production of small to medium capacity. For mass production, we recommend choosing GURT or VMG S as they are equipped with all necessary equipment.