Description

Drying the fruit will remove the water, reducing its weight and size, but the water will not take any energy away, and the fruit will retain all its nutrients, only concentrating to a smaller volume. Dried fruit is rich in vitamins A, B, B1, B2, B3, B6, pantothenic acid, vitamins C and E, minerals such as potassium, magnesium, calcium, iron.

It contains fiber and can cover up to 50% of the recommended daily consumption. With gentle drying, a substantial proportion of the phytochemicals (carotenoids, anthocyanins, folic acid, vitamin C and E) will remain in the fruit, which prevent the oncological and cardiovascular diseases. For example, in prunes you can find high levels of antioxidants and in dried cranberries there are even more than in fresh ones.

Benefits of the dried fruit:

-

The main advantage of drying is to prevent decomposition by rotting bacteria.

-

Dried fruit is rich in vitamins A, B, B1, B2, B3, B6, pantothenic acid, vitamins C and E, minerals such as potassium, magnesium, calcium, iron. It contains fiber and can cover up to 50% of the recommended daily consumption.

-

With gentle drying, a substantial proportion of the phytochemicals (carotenoids, anthocyanins, folic acid, vitamin C and E) will remain in the fruit, which prevent the oncological and cardiovascular diseases. For example, in prunes you can find high levels of antioxidants and in dried cranberries there are even more than in fresh ones.

- Sušené ovocie neobsahuje tuky, nie je zdrojom škodlivých transmastných kyselín a obsahuje minimálne množstvo sodíka preto je vhodné aj pre ľudí s vysokým krvným tlakom. Je zdrojom rastlinnej vlákniny, ktorá je dôležitá pri prevencii proti rakovine.

-

Dried fruit does not contain fats, is not a source of harmful trans-fatty acids and contains a minimum amount of sodium, so it is suitable for people with high blood pressure. It is a source of plant fiber, which is important in preventing cancer.

The initial phase of the technological process for the production of dried fruit takes place by using a complex facility for the storage, handling and preparation of raw materials, water, salt, oil and the like. Special containers are used for storing raw materials.

Features:

- easy operation

- suitable for many different types of fruit

- easy cleaning and maintenance

- low production costs

- high production effectiveness

- automation

The dried fruit production line may consist of the following equipment:

1. Inspection conveyor IC

The device is designed to inspect and manually remove damaged products. Damaged products are removed through the side walls of the conveyor.

2. Conveyor with the hopper ICH

The conveyor can be easily integrated into various technological lines – providing transport of material for further processing.

3. Cutter EasyCut

The processed product is cut into smaller pieces.

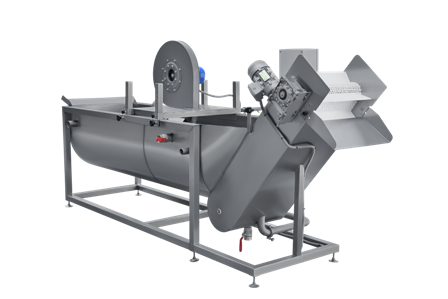

Washing is done by gentle action of air bubbles, which create a special bubble system.

5. Inclined screw blancher Screw I

A large diameter screw is located inside the chamber. The product is moved by means of the screw in the direction of unloading.

6. Dryer

The dryer works on the principle of uniform flow of warm air.

https://normit.com/2019/10/23/dried-fruit-healthy-alternative-of-fresh-fruit/?lang=en