Description

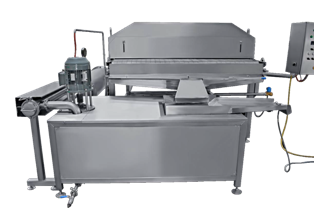

The continuous pouring fryer series is the current boom in the product frying market. Designed by our engineers based on existing practical experience in the manufacturing and use of conveyor deep fryers, the new design provides the best performance and environmental performance indicators.

NORMIT pouring fryers have the lowest oil volume in the system relative to performance, significantly reducing the manufacturer’s costs associated with replacing and recycling of waste oil. The high oil exchange coefficient, its intense circulation and constant filtration ensure the unbeatable quality of the fried product while retaining all its performance properties.

Examples of use

- Chicken legs

- Hamburgers

- Cut rings of eggplants, zucchini

- Nuggets

- Croutons

- Flour products

- And others

Frying method

Pouring with hot oil provides heat transfer results comparable to hot oil immersion and is effectively used to roast even large pieces of meat and fish products, for which frying is a necessity.

Hot oil forms a film on all sides of each piece of product, its intensive circulation between the product and the heating source ensures that the set uniform temperature is maintained throughout the frying surface.

The oil film is also formed on the mesh conveyor below the product. Due to the minimum time of oil transition from the heat source to the product, the oil does not manage to overheat, transmitting the heat energy of the product until heating begins to deteriorate its properties.

High heat exchange indicators ensure roasting efficiency as if the product was constantly mixed in hot oil.

Upon customer request it is possible to install a single or multiple product flipping section.

The deep fryer is frying products very quickly, efficiently and evenly. Hot oil is pouring on the product that moves along the conveyor belt, so the frying takes only a few minutes. The resulting product is uniformly fried, has a uniform color and texture and a perfect golden finish.

Always clean oil – guarantees high quality finished product

Intensive circulation and continuous oil filtration ensures excellent fried product quality and preservation of its nutritional properties. Permanently pure oil is a guarantee of a quality finished product.

The entire volume of oil in Normit continuous fryers is passed through continuous filtration. Smaller product particles are continually collected using special multi-stage filters and the operator visually checks the degree of contamination and the need for filter cleaning. The filter is cleaned while the machine is operating, while the oil is still filtered through the second pair of filters.

Intensive oil circulation between the heat exchanger and the product, as well as precise temperature control, prevents local oil overheating, thanks to which the product’s useful properties does not deteriorate.

Advantages of construction for stable work at high temperatures

-

The construction of the skeleton is characterized by high stability, durability and also longevity.

-

The external drive is not subject to overheating, which could cause deformation and oil leakage from the transmission.

-

Easy-to-remove cover provides thermal insulation and vapor and smoke release through ventilation system and built-in filters.

-

A labyrinth seal is used to prevent the escape of flue gases.

- Operator safety is ensured by a reliable thermal insulation layer.

-

The structure dynamically compensates for the thermal expansion of the metal.

-

On the drive shaft, the toothed wheels are float-mounted, which makes it possible to compensate for the dynamic expansion of the mesh.

Frying net

Used conveyor nets are made of high quality stainless steel, they are very hygienic and easy to clean. Optionally, special “turbo brushes” can be installed to continuously clean the mesh during frying.

When configuring the fryer, the customer chooses the most suitable pattern of the conveyor net according to his product.

Continuous pouring fryers are produced with electric, steam or gas heating.

Filtration:

During frying, the oil is filtered and continuously circulated to prevent oil from deteriorating, during frying, the oil is clean, clear, free of charred product particles that may contain carcinogenic substances. The NORMIT pouring fryer system requires a minimum amount of oil, it does not need to be replaced, it only needs to be added with the quantity left with the product. There is no waste that must be disposed of by law.

The frying time is set by changing the conveyor speed. Thanks to the watering system, the product contains much less oil, resulting in a healthier product. Each piece is evenly fried over the entire length of the conveyor, avoiding local overheating and burning of the product.

Control is provided by automatic control (PLC), which is designed for more complex machines, equipment and production lines, where it is necessary to record temperatures, signal limit parameters, sensing multiple quantities, automatic dosing, level control, time setting, etc. With automatic control it is possible to copy records to PC, connect touch screen or connect to ethernet.

Benefits of NORMIT fryer:

-

Consistent product quality over the entire length and width and uniform temperature distribution

-

Full automation reduces the impact of the human factor in the manufacturing process

-

Up to 20% energy savings

-

Savings for disposal of used oil.

-

The result is a high quality and easily digestible end product

-

The total oil volume is 25-40% lower than in deep fryers

-

The oil is constantly circulating through the filter, it is clean and clear the whole frying time

CONTINUOUS OIL FILTRATION SYSTEM significantly reduces oil replacement costs. The oil is clean and clear at all times during frying, with no charred product particles that may contain carcinogenic substances. The continuous oil filtration system not only extends the longevity of the oil but also ensures a healthier end product.

OIL SUPPLY CONTROL SYSTEM allows you to individually adjust the oil flow rate and parameters such as speed and temperature. It helps you set the optimal frying for your product, as well as allowing you to create several types of different products on the same fryer by only changing parameters.

OIL CIRCULATION SYSTEM – The circulation of oil between the product and the heat exchanger, in which the oil remains in the heated state for only a few seconds, prevents the formation of harmful substances in the oil. The innovative heat exchanger cools the oil quickly after frying.

OIL LEVEL CONTROL SYSTEM– The fryer is equipped with an oil level control system. Thanks to this system, the oil is automatically maintained at a certain level.

Video

Dokumenty

Katalóg