Description

The line for washing, cleaning and cutting sugar beet and chicory ensures processes of preliminary and final thorough washing and cleaning of vegetables and subsequent cutting to the desired shape and size. The line may consist of these devices

I. PRE-WASH

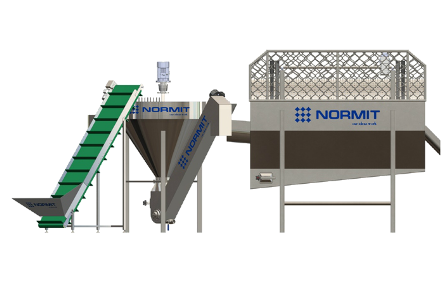

Cyclone stoner with drum washer

A cyclone destoner with a grass catching drum and a drum washer ensure an effective pre-washing of the root vegetables before entering the brush washer. The root vegetable is transferred to a conical container by a conveyor, where it swirls a strong stream of water, which rinses the product, getting rid of lumps, stones and grass and then discharging directly into the drum washer.

Part of the stoner is a drum with sticks for catching grass. The stones and clay are led out of the container by the conveyor. The vegetables are washed in the drum washer and transported to a rotary brush washer where the vegetables are free of the last impurities. Water is constantly circulating from the washing machine to the stoner. Water consumption can be significantly reduced by a drum filter.

B. FINAL WASHING OF VEGETABLES

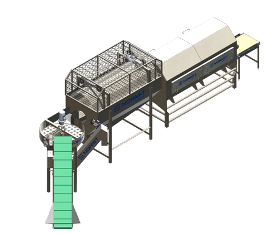

WASHING DEVICE FOR ROOT VEGETABLES NORMIT with rotating drum and rotating brushes

A brush washer ensures that all vegetables and citrus fruits are washed, cleaned and / or polished without damaging the product. The device consists of a rotating drum which rotates in the opposite direction to the rotating brushes, resulting in efficient cleaning.

In the drum there is a shower device, which washes and rinses the product and cleans the device. Rotation speed control is separate for the drum and separate for the brushes. Brushes consist of segments, ensuring easy replacement of only the part of the brush that is damaged or worn.

CUTTING

Vegetable cutter is a universal device for cutting various kinds of vegetables and fruits such as potatoes, carrots, onions, cabbages, peppers, celery, tomatoes, sugar beet, chicory, apples, brussels sprout, cucumbers, aubergines, peaches, pineapples, strawberries and the like. NORMIT cutter can cut products up to 200 mm in diameter.

Principle: The raw product enters the rotating drum in the cutter via hoppers. The centrifugal force pushes the product onto the inner wall of the drum and the blades move it through cutting blades that cut the product into slices. The thickness of the cut is adjustable by changing the gap between the drum wall and the blade of the knife. Additional circular knives cut the slices into strips.

We will design and produce the sugar beet and chicory processing line exactly according to your requirements and needs.