Description

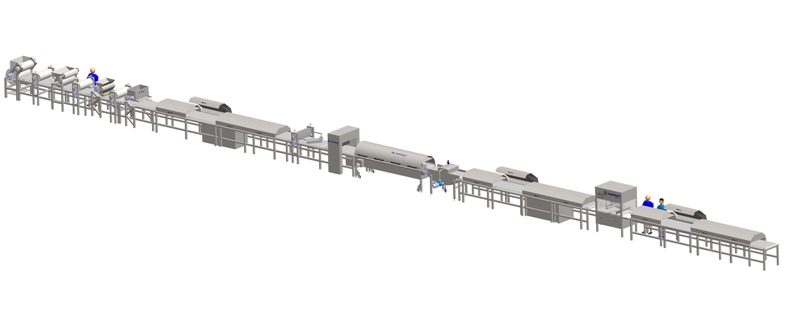

An example of a production line for muesli-based bars

Muesli base – the base material consists of uncooked oatmeal and fruit.

Basic versions of muesli base:

1. dry

The first type of muesli is a loose mixture of oat flakes and pieces of various dried fruits, nuts and seeds. It also normally contains other cereal flakes, such as wheat or rye. There are many kinds of muesli with honey, spices or chocolate.

2. fresh

The second type of muesli is prepared mixture of oatmeal with a juicy base. Common ingredients include sliced or grated fresh fruits (eg bananas, forest berries, grapes, mango), dried fruits, dairy products (eg yogurt, milk), lemon juice, grated nuts, seeds, spices (especially cinnamon) and honey.

Sprinkling

Sprinkling for dipped, semi-dipped or dry product. Nuts or coconut are among the most frequent sprinkles, but other types of sprinkling come to the foreground

Dipping

The bars can be supplemented and combined with yoghurt or milk, thus becoming a source of important proteins.

The cereal bar production line CONTIBAR may consist of equipment that provides the following processes:

The cereal bar production line CONTIBAR may consist of equipment that provides the following processes:

1- Cooking and preparation of mass

2- Mixing and homogenization

3- Extruding

4- Forming of mass

5- Dipping

6- Sprinkling

7- Cooling

8- Cutting

9- Baking

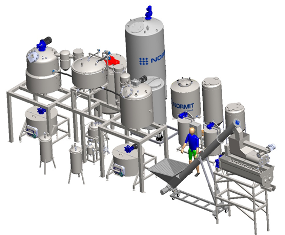

1. Cooking and mass preparation for bars

The composition of the cooking part depends on the specific recipe.

2. Mixing and homogenization

The process of mixing and homogenizing has a great influence on the final structure of the product-texture, due to the proportion of the individual components-such as grain size and taste.

Designed to mix and shape various solid, viscous and paste products. It gives form to the resulting product by slow extrusion of the product under pressure.

4. Forming

The mixture systematically passes through the molding rolls, where by compression a layer is formed according to predetermined dimensions.

Zariadenie je prispôsobené aj na spracovanie jemných, krémových a mierne prevzdušnených zmesí. Hmota sa potom po dopravníkovom páse transportuje do sekcie posypu.

The machine is also suitable for processing fine, creamy and slightly aerated mixtures. The mass is then transported along the conveyor belt to the sprinkling section.

5. Dipping

The mass can be soaked in the coating, sauce, dipping etc.

6. Sprinkling

In this process, the material is sprinkled if necessary.

7. Cooling

Cooling by means of a cooling tunnel works on the principle of bottom cooling by cold water – contact cooling and top cooling by cold air.

8. Cutting

We supply special cutting and forming equipment according to customer requirements. The entire cutting system process consists of three parts – a cutting machine, a product distribution system and a cross cutting machine.

The cutting machine is responsible for properly forming the output. Thanks to the cylinder, the output gets the right shape. The mixture is uniformly cut into strips of equal width according to predefined parameters.

Zariadenie zabezpečí rezanie na pásy o šírke zodpovedajúce šírke hotového výrobku. Systém rozširovania zabraňuje opätovnému prilepeniu narezaného produktu späť k sebe. Zmes sa postupne rozširuje pomocou lopatiek a zachováva tým šírku produktu- narezanú v rezacom stroji. Rovnomerne rozšírené zmesi následne prechádzajú do ďalšieho stroja, kde dochádza k priečnemu rezaniu zmesi podľa vopred definovaných parametrov. Narezané zmesi sú posúvané na ďalšie spracovanie.

The machine ensures cutting to strips with a width corresponding to the width of the finished product. The expansion system prevents the cut product from sticking to itself. The mixture is gradually expanded with blades to maintain the width of the product – cut in the cutting machine. The uniformly expanded mixtures are then transferred to another machine where the mixture is cross-cut according to predefined parameters. The cut mixtures are pushed for further processing.

9. Baking

The tunnel oven ensures uniform heat treatment of the finished product.

10. Soaking of the final product

Ponúkame vhodnú metódu máčania s prihliadnutím na čo najkrajšiu dobu chladenia a stupňa kryštalizácie. Vďaka tomu získava čokoláda, poleva na vzhľade, chuti a lesku. Súčasťou je termoregulačné zariadenie.

We offer a suitable method of soaking taking into account the best cooling time and degree of crystallization. As a result, the chocolate or dipping sauce acquires nice appearance, taste and shine. Thermoregulation device is included.

11. Cooling of the final product

The finished bars that have passed through the soaking section are cooled to the desired temperature.

Of course there is a tempering and control system for the whole line.

We will design and manufacture the production line for making bars exactly according to your requirements.