Product Information

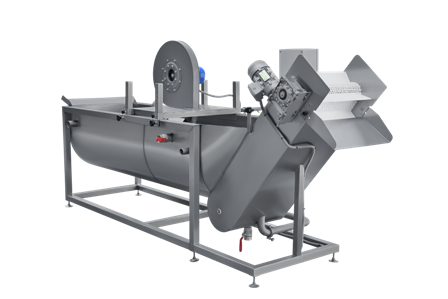

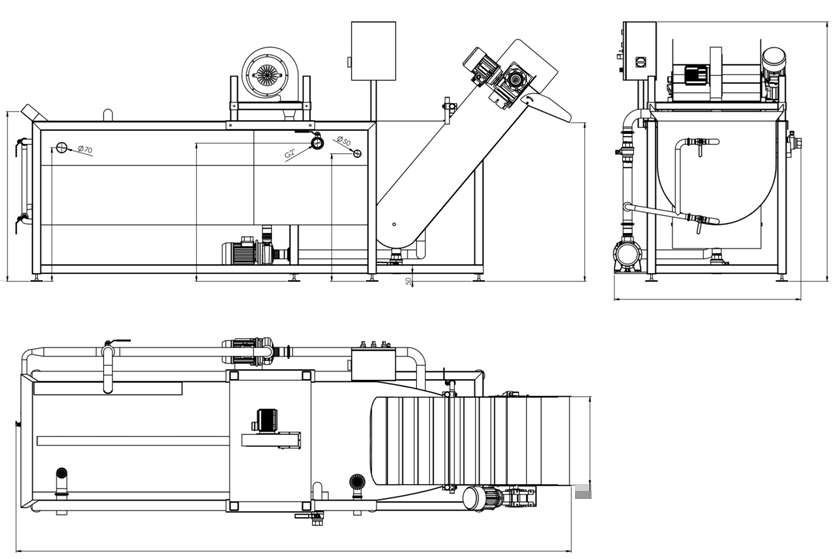

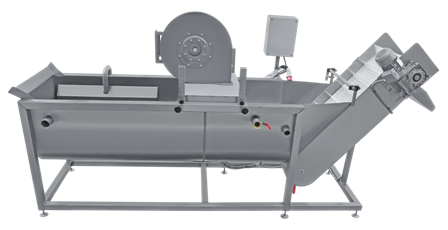

Categories: All, BY ABC, BY INDUSTRY, BY RAW PRODUCTS, Food, Fruit, Plants, herbs, Vegetables, Washer and CIPBubble washer WASH W is a professional appliance designed for efficient and gentle washing of a wide assortment of fruits and vegetables with a fine structure including leaves, light piece and fragile products, grains, legumes and the like.

CONTACT US

Filter produktov

- All (29)

- BY RAW PRODUCTS (58)

- BY ABC (49)

- BY INDUSTRY (51)

- BY PRODUCT (0)

- PODĽA PRODUKTOV (63)

Description

The bubble washer does not have mechanical washing elements, the product is cleaned by the currents produced by the pump.

Washing is done by the gentle effect of air bubbles generated by a special bubble system.

The bubble washer is equipped with two circuits: water circulation and air distribution. The water circulation system ensures product movement along the washing tub, the air generation and distribution system creates a uniform bubble bath over the entire length of the washing tub. Dirt is collected at the bottom of the bathtub under the air jets and the air no longer swirls them (stone separation zone).

In the soaking zone, the product is submerged under water and the product is conveyed to the discharge conveyor by a stream of water. Additional nozzles are installed on the discharge conveyor for the final rinse of the product and also for filling the washing tub with clean water.

Light dirt contamination, dust, insects are removed by overflow and also through a special filter section with a two-stage filter.

Benefits:

- all stainless steel

- highly gentle and efficient washing

- easy to use

- low operating costs

- long service life

- quick and easy cleaning and maintenance

Related Products

Yoghurt production line

The yoghurt production line as a universal cooking homogenizer with pasteurizer designed for a wide range of food products, from liquid to highly viscous, having a homogeneous structure or containing solid particles up to 15 mm (or larger on request).

CONTACT USProduction line for making dried fruit

We will design a tailor-made solution, exactly according to your requirements, from the loading of fruit, washing, peeling, slicing, drying to the packaging of the finished product.

Company NORMIT FOOD s.r.o. designs a solution and manufactures a customized line according to your requirements and needs.

CONTACT USVacuum evaporator SQE

Vacuum evaporators of the SQE series are designed for evaporation of water, thickening and cooking of a wide range of viscous products under vacuum, cooking at lower temperatures, thus preserving the natural taste, aroma and color of the product.

Frozen butter homogenizer

Frozen butter homogenizer is intended for the mechanical processing of frozen blocks of butter, cheese, spreads, margarines or other products without first being subjected to higher temperatures and thawing, thereby preserving its properties, reducing processing time and preparing the product for immediate use in another manufacturing process or for packaging (change from -18 ° C to +6 ° C).

Production line for vacuum-fried fruit chips

Vacuum frying is an innovative way of processing fruit into delicious and healthy chips that are not only tasty but retain all the beneficial ingredients and vitamins. Fruit chips will provide enough energy between meals. They are a great alternative to raw fruits, they are tasty, crunchy and you can always have them at hand.

Making healthy fruit chips has never been easier. With the NORMIT production lines, you can start production right away.

Stand out from others and produce healthy food!

Company NORMIT FOOD s.r.o. designs and manufactures a customized line according to your requirements and needs.

CONTACT USLine for production of semi-finished meat products

The line is an ideal solution for the production of meat products such as meatballs, burgers, meat pancakes and the like.

Company NORMIT FOOD s.r.o. thanks to its many years of experience and teams of experts, will design a solution and produce a tailor-made line according to your requirements and needs.

CONTACT USButter homogenizer

The frozen butter homogenizer is designed for the mechanical processing of blocks of butter, cheese, spreads, margarines or other products at a temperature of +8 to + 13 ° C without being previously exposed to a higher temperature, thereby preserving its properties, reducing processing time and prepare the product for immediate use in the next manufacturing process or for packaging.

Equipment for the production of soya milk

A soy milk production equipment is a device specifically designed for the production of soy milk, which is a healthy alternative to cow's milk. Compared to cow's milk, it contains 51% more protein, 12% less calories, 24% less fat, 15x more iron, no cholesterol.